Solution

PRODUCTION50™

New Possibilities of PRODUCTION50™

Turn on the switch to innovation with us.

Our Industry's situations

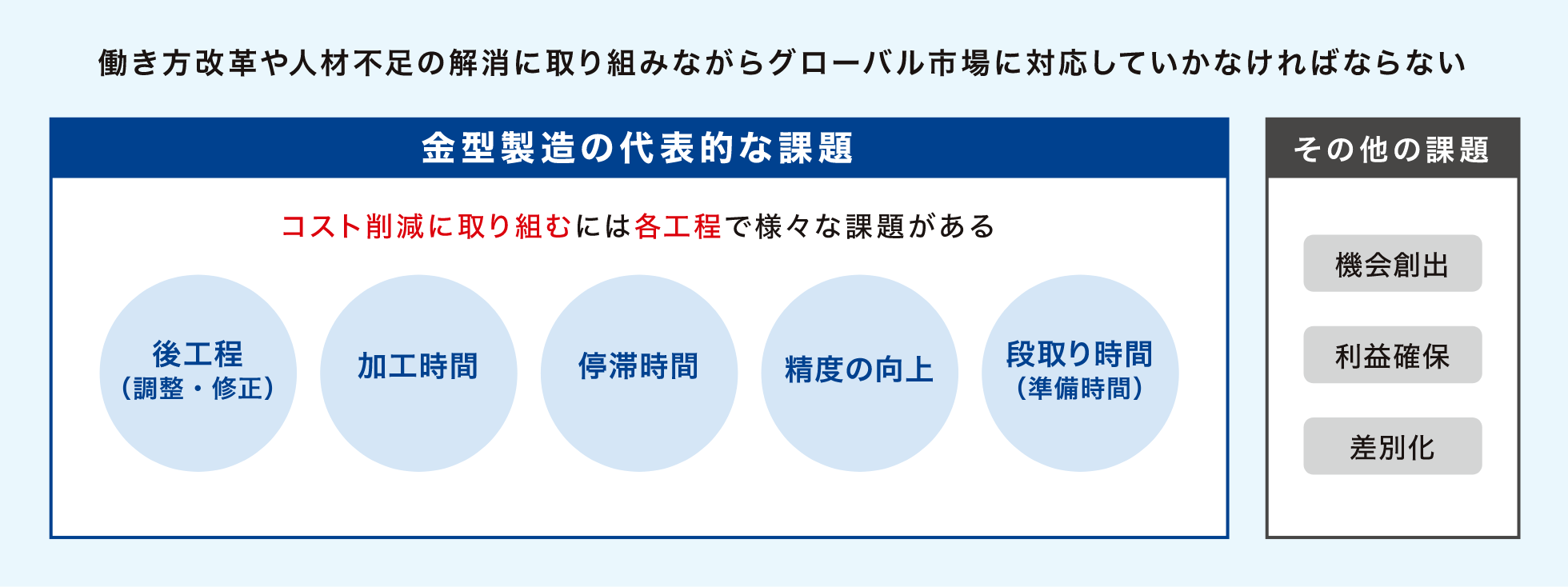

Even as we consider cost reduction, we must also address issues at manufacturing sites while tackling the issues at hand, such as reforming work styles and securing human resources.

Improvements are needed that encompass all processes

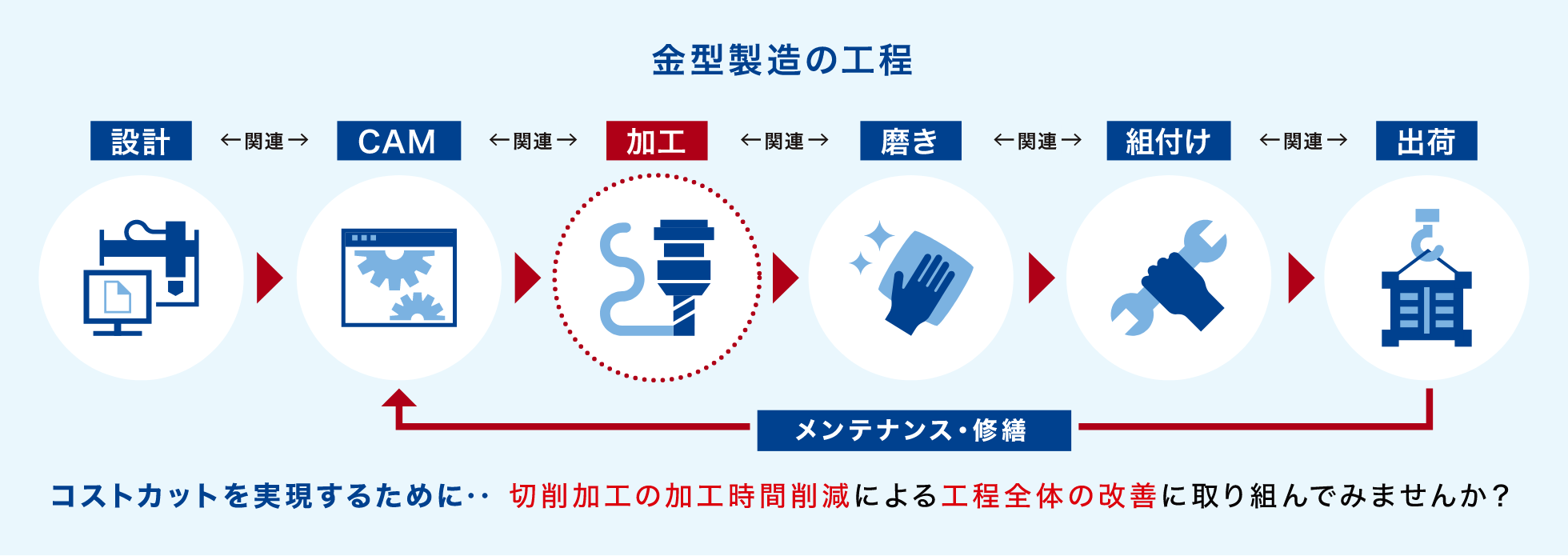

In recent years, the evolution of peripheral equipment and software has deepened the relationship between preand post-processes, and individual countermeasures may not be sufficient to solve the problem. In some cases,individual measures may not be sufficient to solve the problem.

In order to cut costs, it is important to make improvements that encompass all processes.

Please consider introducing PRODUCTION50 ™

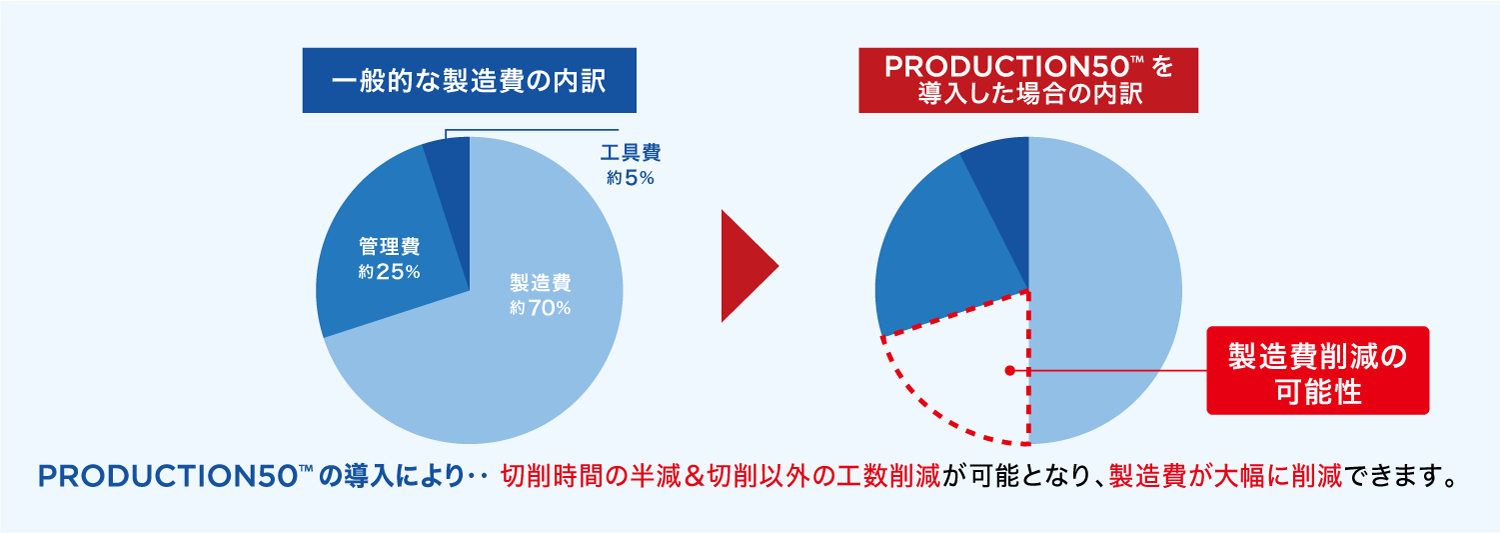

It is said that the time required for the cutting process accounts for 30% to 40% of the total production time.

PRODUCTION50 ™ from MOLDINO first works to halve cutting time by using the latest and most appropriate tools and machining methods.

We then propose cost reductions in man-hours other than cutting, i.e., overall production costs.

Hi-Pre 2

Advantages in the total process including not only machining but also polishing and adjustment

The manufacturing of high-precision dies is greatly influenced not only by the final finishing process, but also by the machining accuracy of the preceding rough and semi-finishing processes.

We pusue high precison from roughing, including polishing and adjustment, aiming to optimize the total process.

Hi-Pre² is an abbreviation for "High Precision Pre-finishing".

Inquiry

Weekdays 10:00-16:00

*Technical Inquiry

Various Inquiry

E-mail magazine registration