Corporate information

About MOLDINO

Founded in 1928.

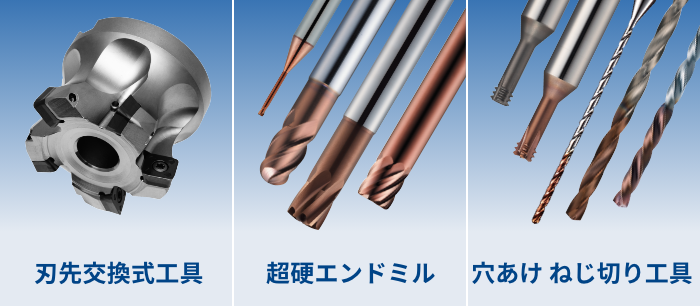

From Indexable Tool to carbide End Mill, Drilling,

MOLDINO offers every cutting tools required for mold machining from indexable tools to carbide end mills, drilling tools, threading tools, and chamfering tools.

MOLDINO grows together with our customers through our unique products and proposal capabilities.

As an original tool manufacturer that honors the pride of our customers, we will continue to challenge unknown territory.

brand message

Technology thoroughly applies in the service of people and goods

Technology that values the accumulation of results

Technology that brings marvels and smiles

MOLDINO Tool Engineering, innovative product development

Our principles are to…

be embodied in our technology

Stand together with our customers

Respond to each and every challenge for as long as necessary

Use great ideas to the creation of unique, world-beating products

Be a step ahead in fulfilling customers' dreams and visions

Take a holistic view toward manufacturing innovation

As earnest in our approach as our technology itself

Committed to doing all we can do for our customers here and now

At MOLDINO Tool Engineering…We grow with our customers and share in their pride, Taking on the challenge of exploring

The Edge To Innovation

MOLDINO vision

To respond earnestly to challenge of a customer

To keep exploring

To grow together with a customer

To be an indispensable partner of a customer

We are happy, when customers are happy

our passion

Mold and die, foundation for manufacturing

Works coming from integration of expertise and latest technology

Essential to Japan as one of finest results of technology

Our mission to keep polishing Japan brand

Age always leads development of technology

Bringing innovation toward coming ideals of mold and die

That is MOLDINO of our pride

Three strengths of MOLDINO

Development technology

![[開発技術]金属製造に加工イノベーションを](/assets/img/company/brand/fig02_01.png)

Complete in-house from materials to development, production, and inspection Creative tools specializing in molds

The driving force behind MOLDINO, which offers everything from Indexable Tools, End Mills, Drilling, threading, and chamfering tools, is our three plants in Japan. The Narita Plant develops and manufactures carbide materials and Indexable Tools. The Yasu Plant handles everything from solid tools to regrinding and recoating. And the Uozu Plant supports stable production. We respond to various needs with "originality" that makes the most of each characteristic.

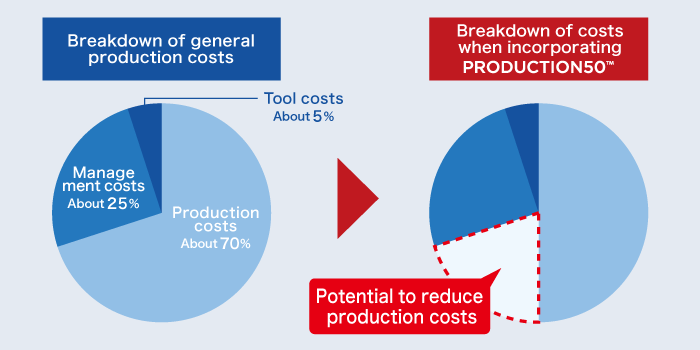

PRODUCTION50 ™

![[加工半減]金属製造に加工イノベーションを](/assets/img/company/brand/fig02_04.png)

Cutting costs in half with high performance and efficiency Towards the future of mold machining

MOLDINO's "PRODUCTION50 ™-Halving processing-" concept, which brings about strengthening of international competitiveness by shortening the delivery time and reducing costs of mold manufacturing, focuses on "manufacturing costs" (costs in terms of time). By using high-performance tools, we aim to improve processing efficiency and reduce total costs in mold processing, and build a foundation for the future while increasing profits.

We aim to reduce manufacturing costs with the latest and most suitable tools and processing methods.

Solution selling

![[提案営業]金属製造に加工イノベーションを](/assets/img/company/brand/fig02_06.png)

Useful and real-time support Your partner in mold manufacturing

Problems at manufacturing sites that change with the times. We quickly catch not only actual problems but also potential issues and take appropriate next steps. Our staff, who are familiar with cutting, will propose solutions that fits your needs.

We provide flexible support according to the situation, such as online meetings and processing proposals.

Inquiry

Weekdays 10:00-16:00

*Technical Inquiry

Various Inquiry

E-mail magazine registration