Solution

PRODUCTION50™

New Possibilities of PRODUCTION50™

Turn on the switch to innovation with us.

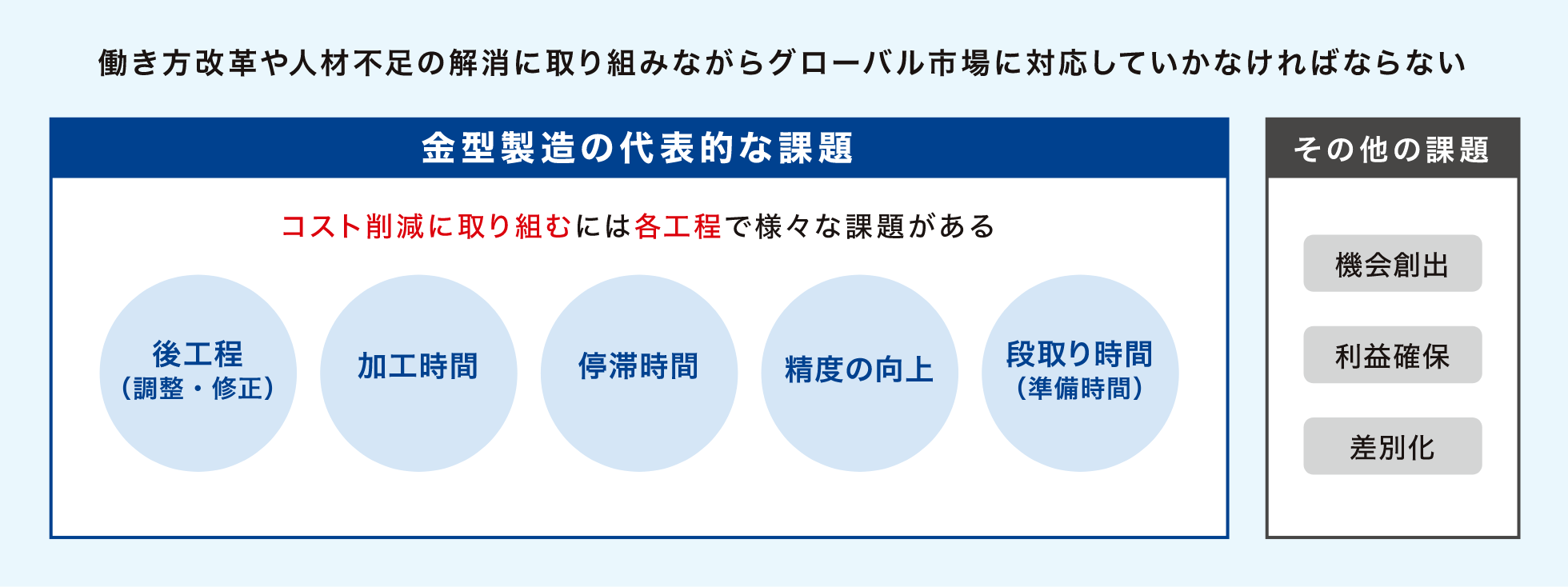

Environment Surrounding Manufacturing Sites

Even if we consider cost reduction, we have to solve problems at the manufacturing site while working on immediate issues such as work style reform and securing human resources.

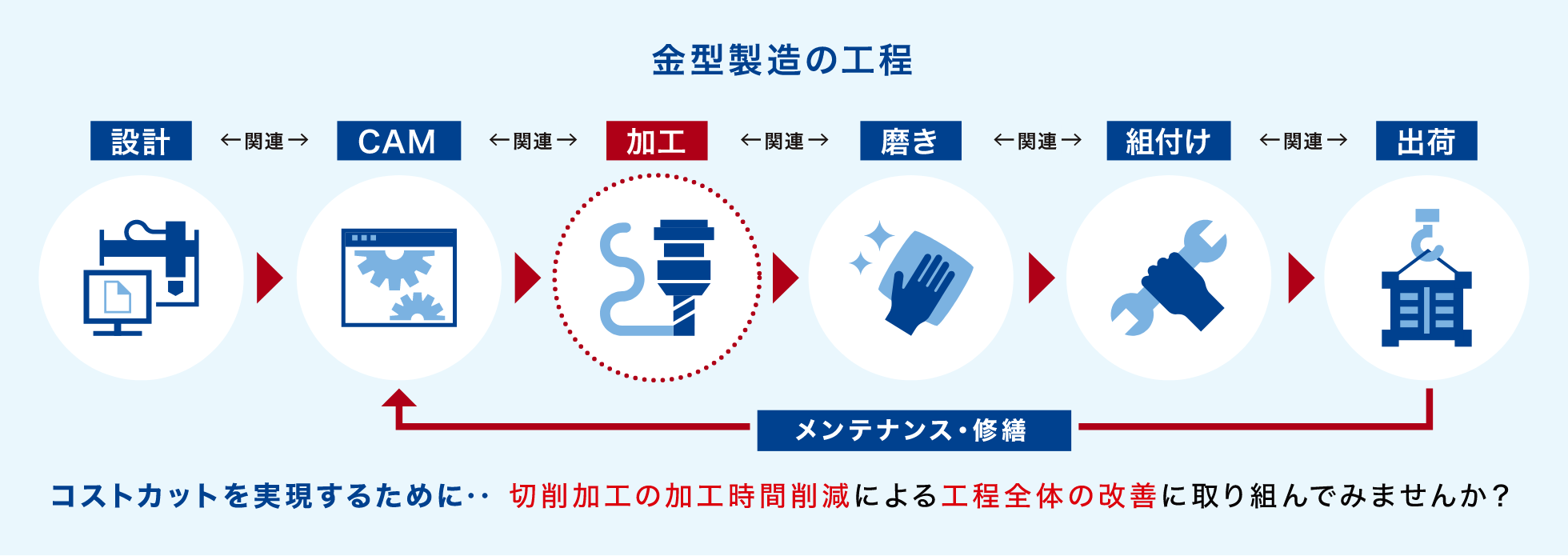

Improvements that overlook the entire process are necessary

In recent years, due to the evolution of peripheral devices and software, the relationship between pre- and post-processes has become even deeper, and in some cases individual measures cannot be sufficient.

"Overall improvement" is an important point to achieve cost reduction.

Please consider introducing PRODUCTION50 ™

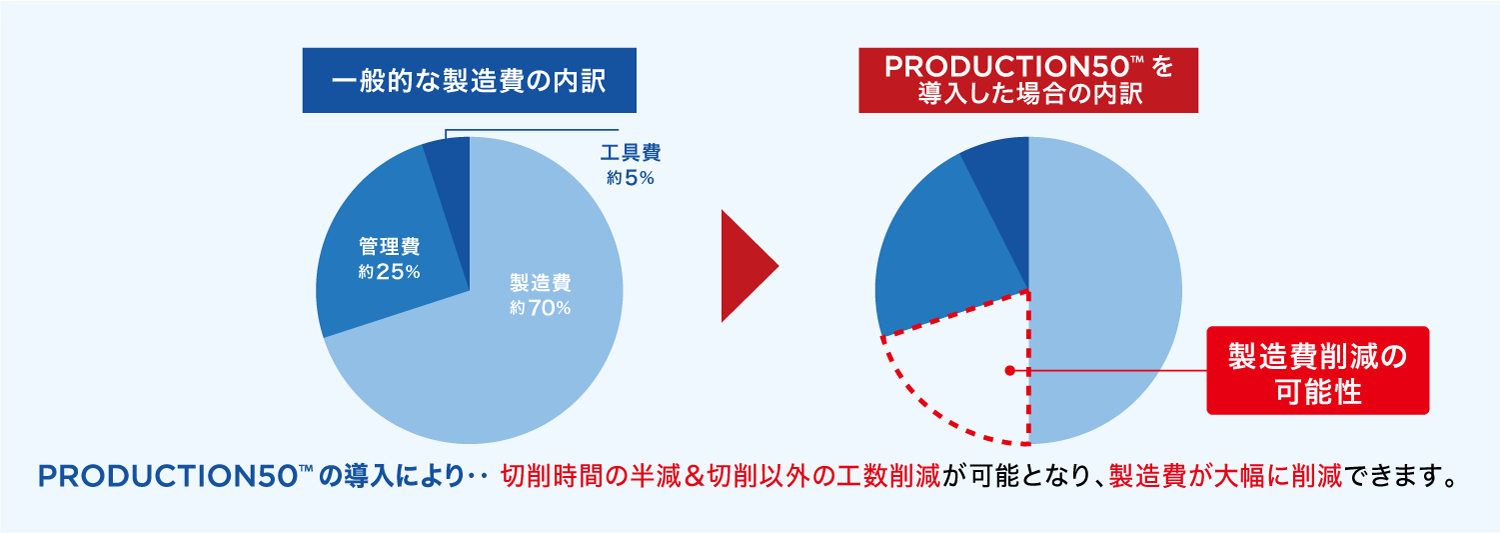

It is said that the time required for the cutting process in all manufacturing is 30% to 40%.

MOLDINO's "PRODUCTION50 ™" first works to halve the cutting time by using the latest and most suitable tools and processing methods.

Then, we will make proposals for man-hours other than cutting, that is, cost cutting of the entire manufacturing cost.

Hi-Pre 2

Advantages in the total process including not only machining but also polishing and adjustment

The production of high-precision molds is not only affected by the final finishing process, but also by the machining accuracy of the preceding rough and semi-finishing processes.

Pursue high precision from rough machining, and aim for optimization in the total process including polishing and adjustment! This is the "Hi-Pre²" advocated by MOLDINO.

Hi-Pre² stands for "High Precision Pre-finishing".

Inquiry

Weekdays 10:00-16:00

*Technical Inquiry

Various Inquiry

E-mail magazine registration