Solutions

PRODUCTION50™

New possibilities with PRODUCTION50™

The switch to innovation is right here.

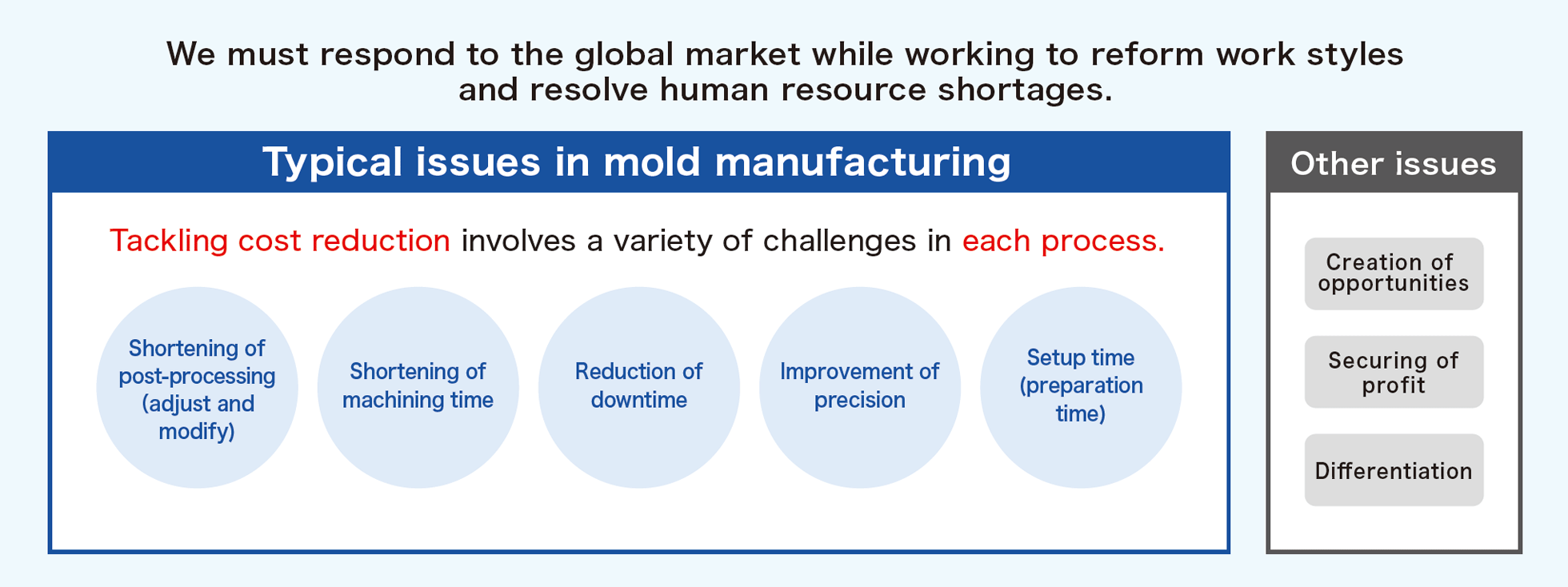

Environment Surrounding Manufacturing Sites

While considering cost reductions, we also need to address issues at manufacturing sites while also addressing other relevant issues, such as reforming working styles and securing human resources.

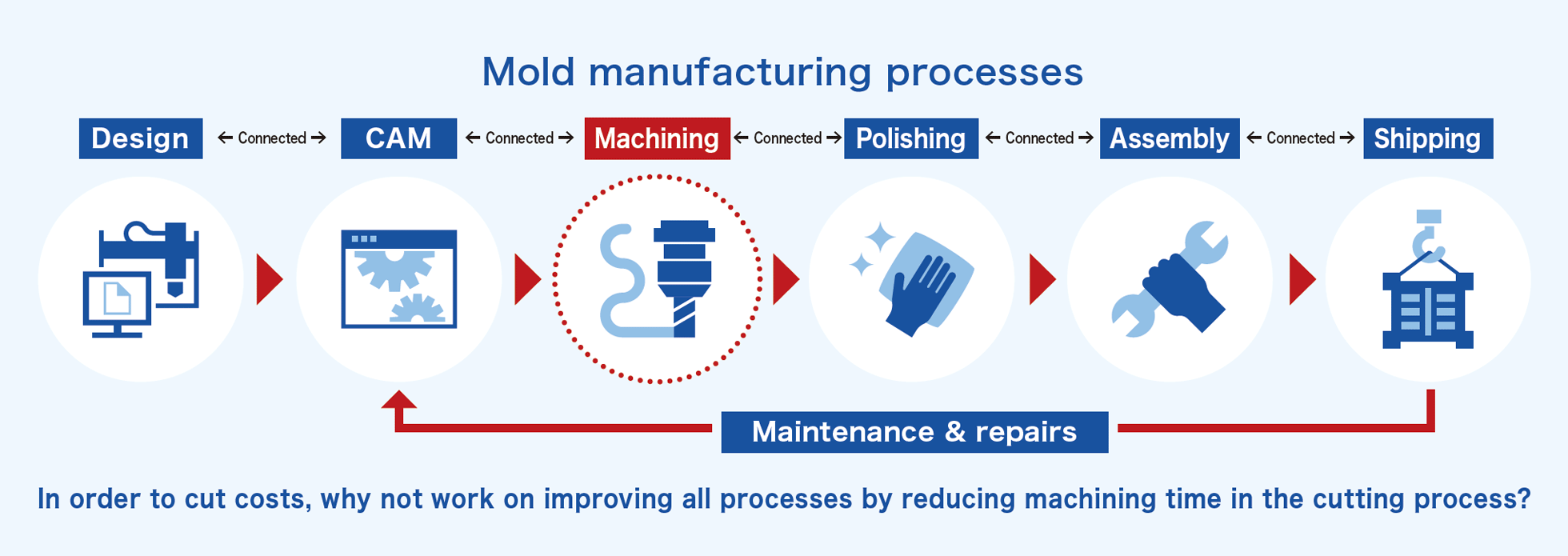

We need improvements to cover all processes

Advances made in peripheral equipment and software in recent years have further deepened the relationship between pre- and post- processes, and individual measures may not be sufficient to solve the problem.

To realize cost reductions, it is important to have "improvements that look at the entire process."

Please consider purchasing PRODUCTION50™

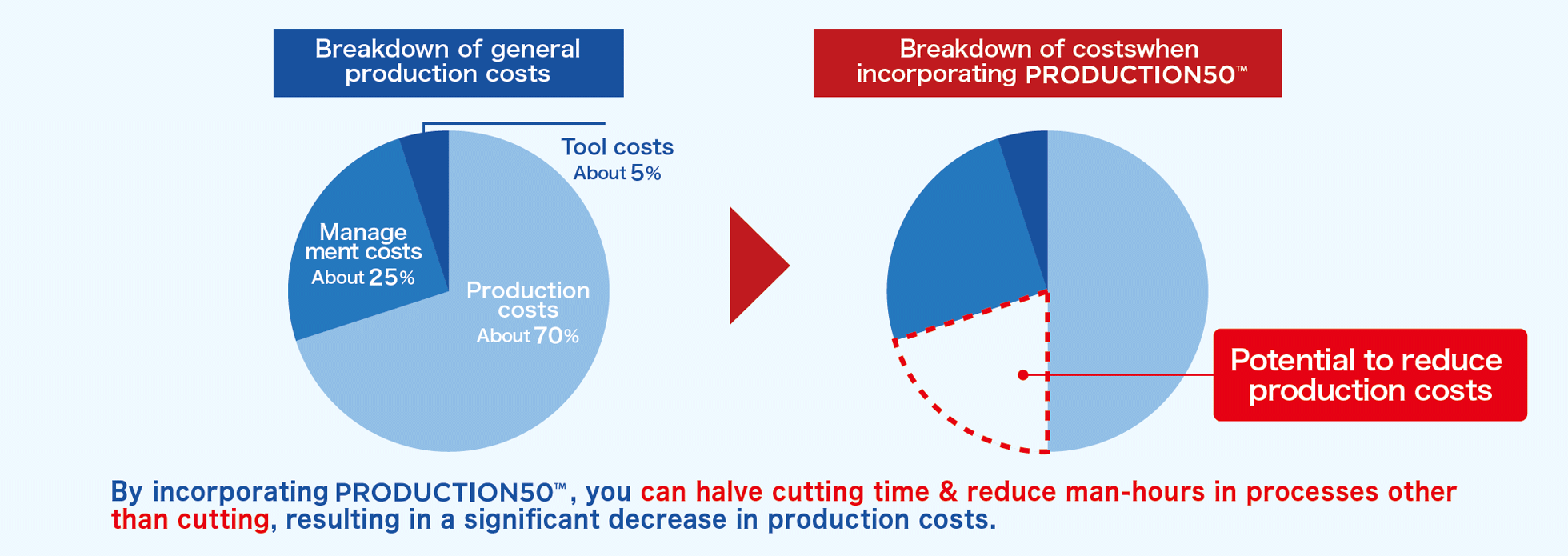

Cutting processes are estimated to take up 30% to 40% of the total production time.

MOLDINO's "PRODUCTION50™" first works to reduce cutting time by half using the latest and greatest tools and machining methods.

Cost reductions are then proposed in terms of a reduction in non-cutting man-hours (i.e., overall manufacturing costs).

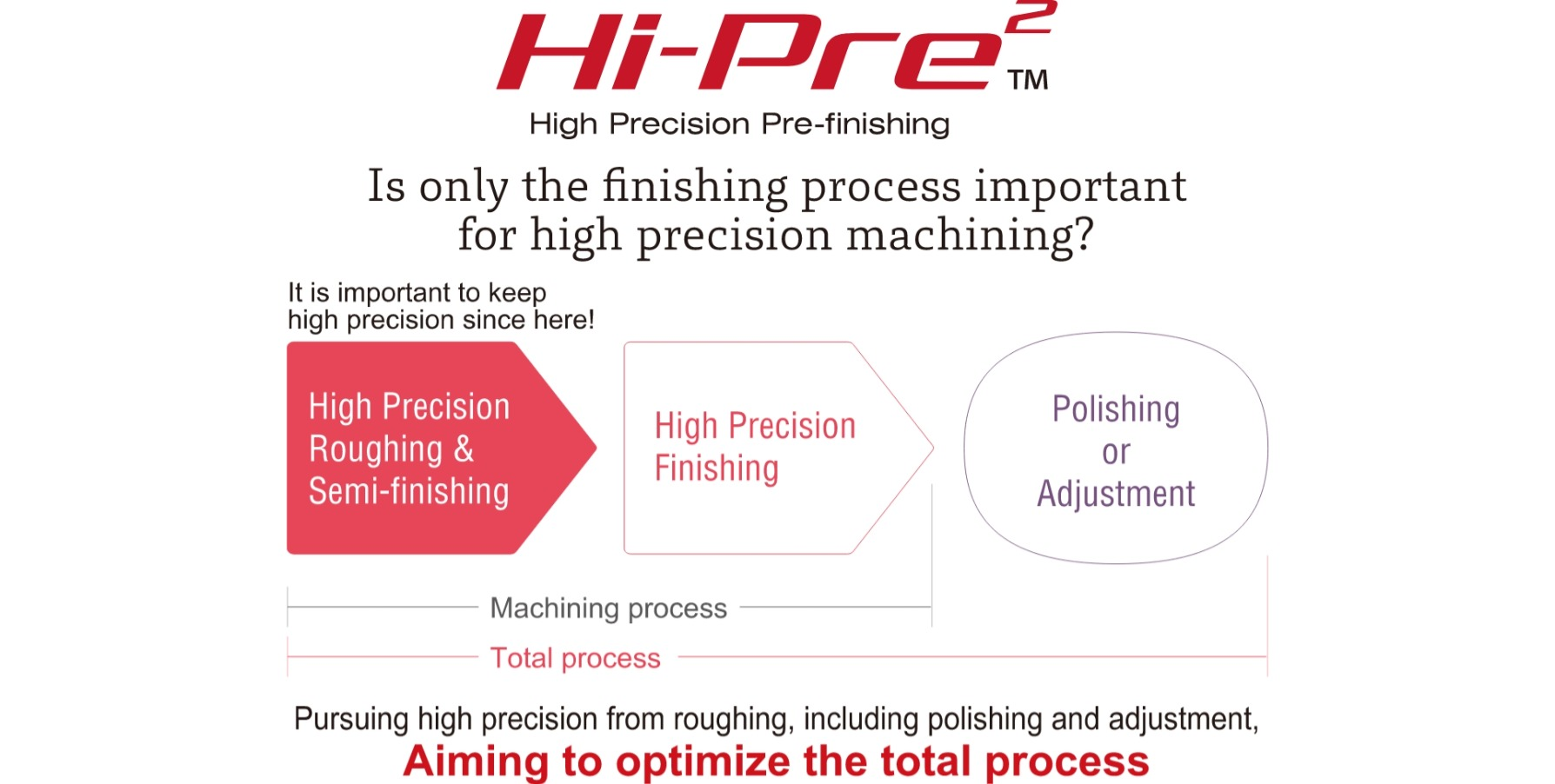

Hi-Pre2

When manufacturing high-precision molds, the total process includes not only machining, but also polishing and adjustment.

These have a significant impact on the machining accuracy not only in the final finishing process, but also in the rough and semi-finishing processes that precede it.

We pursue high levels of precision and aim to optimize the total process, from rough machining to polishing and adjustment!

Hi-Pre² is an abbreviation for "High Precision Pre-finishing."

Contact us

Various inquiries